- 您现在的位置:买卖IC网 > Sheet目录240 > PAXLSG00 (Red Lion Controls)METER STRAIN GAGE 3 1/2-DIGIT

�� �

�

�

�5.0� C� ALIBRATING�

�THE�

�M� ETER�

�There� are� three� different� methods� that� can� be� used� to� calibrate� the� PAXLSG,�

�and� the� method� chosen� depends� largely� on� the� nature� of� the� application.� The�

�three� methods� are:�

�VOLTAGE� CALIBRATION�

�In� this� method,� the� transducer� signal� is� simply� replaced� with� an� accurately�

�measured� input� voltage� that� can� be� varied� through� the� range� normally� delivered�

�by� the� transducer� (See� Voltage� Calibration� Circuit,� below).� The� PAXLSG� is� then�

�adjusted� to� provide� the� proper� readout.�

�SYSTEM� CALIBRATION�

�In� this� method,� the� transducer� is� connected� to� the� input� of� the� PAXLSG� in� the�

�final� installation,� or� in� a� bench� set-up� simulating� the� actual� installation.�

�Accurately� known� inputs� are� then� applied� to� the� transducer� (i.e.� load,� pressure,�

�force,� etc.),� and� the� PAXLSG� adjustments� are� made� to� provide� the� desired�

�indication.� This� method� is� usually� preferable� to� the� Voltage� Calibration� method�

�since� it� calibrates� both� the� transducer� and� the� PAXLSG� as� a� combination,� and�

�reduces� the� inherent� risk� of� inaccuracy� or� errors� accumulated� by� separate�

�calibration.� However,� it� can� only� be� used� in� applications� where� the� parameter� to�

�be� indicated� can� be� easily� varied� and� accurately� measured� or� established.� It� is�

�also� very� awkward� to� use� if� an� offset� or� transducer� unbalance� must� be� dealt� with�

�because� of� Offset/Gain� adjustment� interaction.�

�COMBINATION� VOLTAGE/SYSTEM� CALIBRATION�

�In� applications� where� tare-load,� offset,� or� substantial� transducer� unbalance�

�EXAMPLE� :� Readout� is� to� be� 5.00� Units� @� 2� mV� minimum,� and� 15.00� Units�

�@� 18� mV� maximum.� The� transducer� is� a� 350� ?� strain-gage� bridge� requiring�

�10� VDC� excitation.�

�Rs� =� 1500� -� 500� =� 1000� Units�

�Vs� =� 18� mV� -� 2� mV� =� 16� mV�

�GAIN� =� 1000� =� 62.5� Units/mV�

�16�

�Note:� While� most� strain� gage� readout� applications� are� zero-based� (i.e.� zero�

�readout� @� zero� input)� this� example� was� intentionally� chosen� because� it� included�

�an� offset� reading� at� zero� input.� It� will� be� used� in� the� Calibration� Procedure�

�below� to� illustrate� the� most� convenient� way� to� handle� offset� situations� without�

�excessive� interaction� of� gain� and� offset� adjustments.� If� a� zero-based� example�

�had� been� given,� the� minimum� readout� and� input� voltage� would� have� both� been�

�zero.� Rs� and� Vs� would� then� simply� be� the� maximum� values� of� readout� and� input�

�voltage� respectively,� gain� would� just� be� the� ratio� of� (Max.� Readout/Max.� Input�

�mV),� and� Steps� 7� and� 8� of� the� procedure� below� could� be� eliminated.�

�CALIBRATION� PROCEDURE�

�1.� Set� the� Coarse� Gain� Select� Switches,� S5� through� S9� to� establish� a� maximum�

�range� just� exceeding� the� required� gain.� Referring� to� the� example� given,� the�

�required� gain� was� calculated� to� be� 62.5� Units/mV.� Setting� switches� S6� and� S7�

�ON� gives� 50� +� 16� =� 66� Units/mV,� which� is� just� above� the� required� amount.� The�

�following� chart� gives� an� approximate� gain� adjustment� value� for� each� switch:�

�SWITCH� NUMBER� SPAN� VALUE�

�exists� and� where� high� accuracy� is� required� in� the� final� indication,� it� may� be�

�desirable� to� voltage� calibrate� the� unit� first� to� get� it� very� close� to� its� final� settings.�

�Then,� after� final� installation,� the� unit� can� be� “tweaked”� to� its� final� settings� while�

�using� accurately� known� inputs� to� the� system.� These� various� factors� make� it�

�impossible� to� set� up� one� calibration� procedure� to� cover� all� applications.�

�However,� using� the� following� information� on� Voltage� Calibration� together� with�

�5�

�6�

�7�

�8�

�9�

�140�

�50�

�16�

�6.6�

�3.3�

�the� examples� given� should� provide� a� good� basis� for� handling� virtually� any�

�calibration� requirement.�

�CALIBRATION� EXAMPLE�

�“Voltage� Calibration”� can� be� easily� performed� for� any� application,� using� the�

�calibration� circuit� shown� below.�

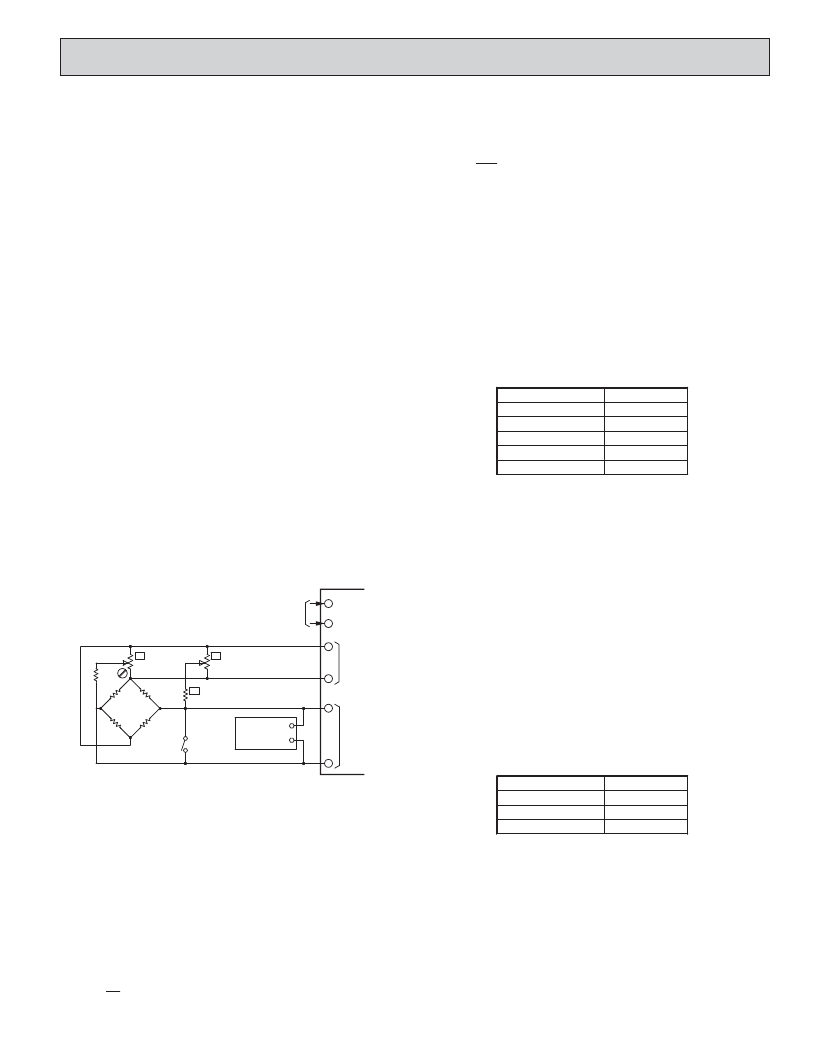

�VOLTAGE� CALIBRATION� CIRCUIT�

�All� offset� switches,� S2,� 3,� and� 4,� should� be� off.�

�2.� Connect� the� unit� to� the� Calibration� Circuit� as� shown.� Set� the� excitation�

�voltage� range� jumper� to� the� 10� V� position.�

�3.� Place� unit� in� the� case� and� turn� power� on� to� the� unit.� Allow� 10� minutes� of�

�warm-up� time� for� stabilization.�

�4.� Close� the� “Zero� Switch”� of� the� calibration� circuit� to� obtain� zero� input� voltage.�

�Adjust� the� fine� offset� control� to� get� a� zero� readout.�

�5.� Open� the� “Zero� Switch”� of� the� calibrating� circuit� and� set� the� input� voltage� to�

�(Using� 350� Ohm� Dummy� Bridge)�

�A.C.� POWER�

�50/60� HZ�

�1�

�2�

�PAXLSG�

�the� calculated� swing� voltage,� Vs.� (Vs� is� 16� mV� in� the� example� given.)� Now,�

�adjust� the� Gain� Coarse� and� Fine� Controls� to� get� a� readout� equal� to� the�

�Readout� Span.�

�(Rs� =� 1000� Units� in� the� example� given.)�

�R2� BRIDGE�

�BAL.�

�1K�

�R1� CAL.� VOLTAGE� ADJ.�

�1K� 10-T� HIGH� RESOLUTION�

�POTENTIOMETER�

�(-)�

�3�

�(+)�

�4�

�EXCITATION�

�VOLTAGE�

�SET� AT� 10VDC�

�6.� Repeat� Step� 4� and� readjust� zero� if� required.� If� zero� readjustment� was� needed,�

�repeat� Step� 5,� then� back� to� Step� 4,� etc.,� until� Zero� and� Rs� readings� are�

�acceptable.�

�*7.� Set� the� calibration� voltage� to� the� minimum� input� level� (2� mV� in� this�

�R3�

�example).� Record� the� meter� reading� (125� in� this� example).� Power� the� meter�

�DUMMY�

�BRIDGE�

�40K�

�REFERENCE� (+)�

�MILLIVOLT�

�(+)�

�5�

�SIGNAL�

�down� and� remove� it� from� the� case.� Set� the� Coarse� Offset� Select� Switches� to�

�get� the� corresponding� minimum� readout� (add� the� switch� offset� value(s)� to� the�

�recorded� meter� reading).� In� the� example� given,� the� minimum� readout� was�

�ZERO�

�SWITCH�

�METER�

�(-)�

�(-)�

�INPUT�

�500� units� @� 2� mV,� therefore� setting� switches� 3� and� 4� gives� us� 125� (meter�

�reading)� +� 125� (SW4)� +� 250� (SW3)� =� 500.� The� following� chart� gives� an�

�6�

�approximate� offset� adjustment� value� for� each� switch.�

�This� 350� Ohms� “Dummy� Bridge”� circuit� delivers� calibration� voltages� in�

�ranges� of� 0� to� ±22� mV,� 0� to� +44� mV,� or� 0� to� -44� mV,� depending� on� the� setting�

�of� R2.� The� range� can� be� increased� or� decreased� by� adjusting� the� value� of� R3�

�(shown� as� 40� K)� .� An� accurate� reference� millivoltmeter� is� used� to� set� up� the�

�SWITCH� NUMBER�

�2�

�3�

�4�

�OFFSET� VALUE�

�500�

�250�

�125�

�calibration� voltage,� and� a� “Zero� Switch”� facilitates� balancing� without�

�readjusting� the� calibration� voltage.� High-stability� metalized� resistors� (1%� tol.)�

�should� be� used.� The� use� of� a� dummy� bridge� insures� a� common-mode� voltage�

�during� calibration� that� is� very� similar� to� that� of� the� actual� transducer.�

�SET-UP� :�

�Before� starting� the� procedure,� the� Input� Swing� Voltage� (Vs),� the� Readout�

�Span� (Rs)� and� the� required� GAIN� must� be� determined.�

�WHERE� :�

�Rs� =� (Max.� Numerical� Display)� -� (Min.� Numerical� Display)� Disregard� Decimal� Points�

�Vs� =� (mV� in� @� Max.� Display)� -� (mV� in� @� Min.� Display)�

�GAIN� =� Rs� =� Units/mV�

�Vs�

�7�

�*8.� Place� unit� in� the� case� and� turn� power� on� to� the� unit.� Use� the� fine� offset�

�adjustment� to� fine� tune� the� desired� minimum� reading� (500� in� this� example).�

�Vary� the� input� from� the� minimum� to� maximum� levels� and� check� the�

�corresponding� readouts.� Fine-tune� if� necessary� by� readjusting� the� fine� gain�

�adjustment� at� the� maximum� end� and� the� fine� offset� adjustment� at� the�

�minimum� end.� (In� the� example,� readout� is� 500� @� 2� mV� min.� and� 1500� @� 18�

�mV� max.)� Alternate� between� minimum� and� maximum� inputs� as� required�

�until� readout� is� within� desired� tolerance� at� the� extremes.9.� Set� appropriate�

�decimal� point� switch� (S2� for� the� example� given).�

�The� unit� is� now� ready� for� installation.�

�*� Steps� 7� and� 8� are� not� required� in� zero-based� applications.�

�发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

PAXLTC00

METER THERMOCOUPLE 4-DIGIT

PAXLVA00

VOLTMETER AC 3 1/2-DIGIT

PAXLVD00

VOLTMETER DC 3 1/2-DIGIT

PAXTM100

TIMER DISPLAY 1/8 DIN PRESET 6 D

PB-1583-TF

BOX ABS 4.37X3.12X2" BK 1=10PCS

PB-1583

BOX ABS 4.37X3.12X2" BK 1=10PCS

PBS-11273

BOX ABS 6.30" X 3.75" X 1.41" BK

PBS-11275

BOX ABS 6.30" X 3.75" X 1.41" BK

相关代理商/技术参数

PAXLT000

制造商:Red Lion Controls 功能描述:METER, TC/RTD TEMP WITH DUAL RELAY 制造商:Red Lion Controls 功能描述:TC/RTD TEMP WITH DUAL RELAY

PAXLT0U0

制造商:Red Lion Controls 功能描述:METER, UL LISTED TC/RTD TEMP W/ D RELAY 制造商:Red Lion Controls 功能描述:UL LISTED TC/RTD TEMP WITH DUAL

PAXLTC00

功能描述:METER THERMOCOUPLE 4-DIGIT RoHS:否 类别:工业控制,仪表 >> 仪表 - 面板,数字 系列:PAX®LITE 标准包装:12 系列:* 其它名称:Q7072030

PAXLVA00

功能描述:VOLTMETER AC 3 1/2-DIGIT RoHS:是 类别:工业控制,仪表 >> 仪表 - 面板,数字 系列:PAX®LITE 标准包装:12 系列:* 其它名称:Q7072030

PAXLVD00

功能描述:VOLTMETER DC 3 1/2-DIGIT RoHS:是 类别:工业控制,仪表 >> 仪表 - 面板,数字 系列:PAX®LITE 标准包装:12 系列:* 其它名称:Q7072030

PAXOEMS1

制造商:Red Lion Controls 功能描述:SOFTWARE AND USB CABLE RS232

PAXOEMSS

制造商:Red Lion Controls 功能描述:SOFTWARE AND CABLE RS232 制造商:Red Lion Controls 功能描述:SOFTWARE AND CABLE, RS232 制造商:Red Lion Controls 功能描述:SOFTWARE AND CABLE, RS232; For Use With:PAXI Counter Display; SVHC:No SVHC (19-Dec-2012) ;RoHS Compliant: Yes

PAXP0000

制造商:Red Lion Controls 功能描述:Meter, Process, 5 Digit .56" Red LED Display, Power: 85-250 VAC 制造商:Red Lion Controls 功能描述:PROCESS INPUT FIELD 制造商:Red Lion Controls 功能描述:Process Meter 制造商:Red Lion Controls 功能描述:PROCESS METER, 85VAC TO 250VAC; No. of Digits / Alpha:5; Meter Function:DC Milliamps / DC Volts; Meter Range:-2mA to +26mA / -1V to +13V; Digit Height:14.2mm; Panel Cutout Height:44.96mm; Panel Cutout Width:91.95mm ;RoHS Compliant: Yes